Megasonics for Olive Oil Recovery

SIEF supports technologies improving Virgin Olive Oil extraction

Background

The CSIRO team have developed an innovative and novel solution to improving physical extraction efficiencies in olive oil production using high frequency ultrasound, known as Megasonics.

Megasonics refers to the application of ultrasound waves in the high frequency range (>0.4 to several megahertz) to separate particles. When pressed or macerated oil-bearing fruit paste or liquid sludges are pre-treated with Megasonics, oil is released through ultrasonic microbubbles and vibrations accessing remote areas within the material’s microstructure and by promoting coalescence effects. Prior to SIEF’s involvement, the CSIRO research had successfully translated the technology from the palm oil production to olive oil and demonstrated it a the laboratory scale.

The Challenge

There is existing demand from the Australian and global olive oil industry to implement a technology that improves oil yields and provides greater returns through physical extraction methods.

Industrial 3 tonnes per hour Megasonics demonstration of olive oil extraction. Source: CSIRO

There are a number of challenges currently affecting the local industry including the short window for processing olives of about two months per year, the cost of malaxation, access to international markets being limited by the domestic use of enzymes in production to enhance extraction and the costly use of these enzymes.

The response

CSIRO’s Megasonics solution addresses the above mentioned challenges by facilitating greater extraction of olive oil or reducing the need for enzymes and the malaxation processing time (and therefore decreasing the need for capital and running costs).

SIEF provided the financial investment to purchase the transducers and CSIRO (with contractors) built and scaled the technology to the 3 tonne per hour size. The prototype was installed in a industrial facility with commerical partner, Boundary Bend Ltd, and trialled during the 2018 season.

SIEF’s Role

The SIEF project played an instrumental role in de-risking the scale-up demonstration in an olive oil commercial facility for the first time by enabling the purchase of a larger number of transducers required for a larger vessel. CSIRO researchers noted that the industry contributed in-kind time and equipment for research trials but was not willing to invest cash. Without the SIEF financial cash investment the demonstration of the Megasonics technology at 3 tonnes/hour would not have been possible.

Outputs

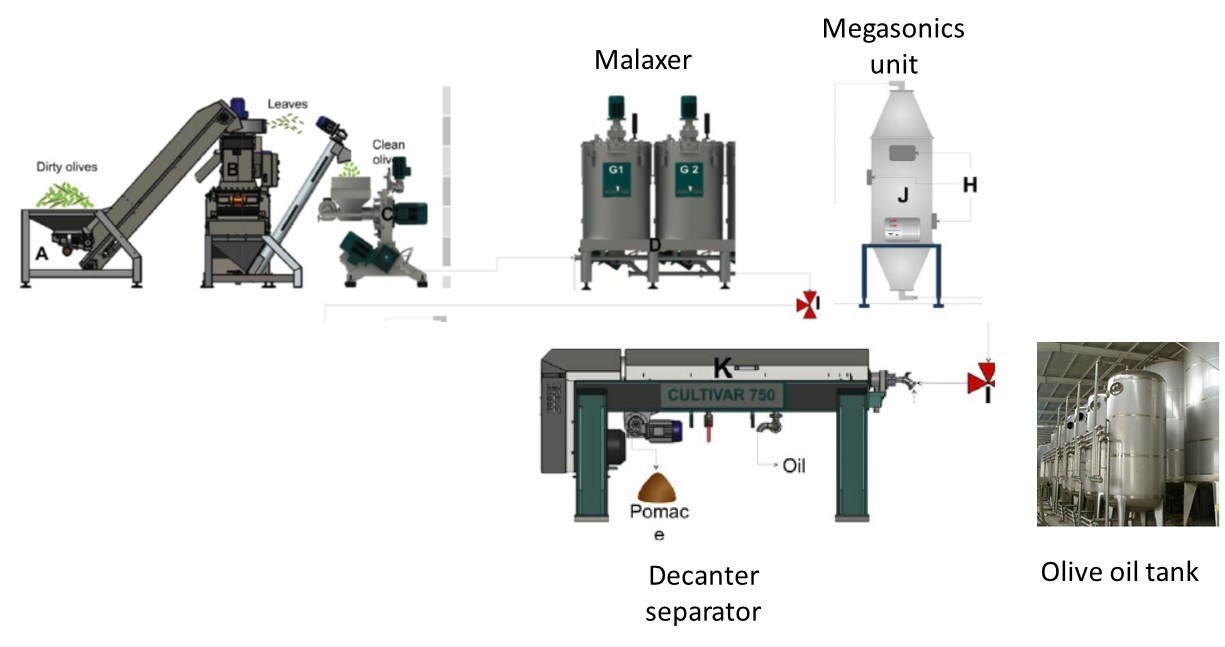

Schematic diagram of a typical olive oil process including the Megasonics unit. SOURCE: CSIRO

The key output of the project was the successfull demonstration of the Megasonics technology at the 3 tonne/hour industrial scale in a commerical facility for the first time. Figure 2 illustrates the addition of the Megasonics unit to a typical olive oil processing line. At 3 tonnes/hour, up to an additional 3.7% of olive oil from the total oil recovered was demonstrated, maintaining olive oil shelf life and quality despite faster and more efficient production process.

- Reduction in production costs due to potentially reducing addition of expensive enzymes

- Production of olive oil with a higher phenolic content

- Possible development of a continuous process for olive oil extraction

- Possible ability to shorten malaxation time by 30 minutes at an industrial scale if desired

Other outputs of the research include:

- Finalist, ANSTO (Australian Nuclear Science and Technology Organisation) Eureka Prize for Innovative Use of Technology, 2018

- IFT Food Expo Innovation Award, United States (Megasonic technology), 2016

- CSIRO Julius Career Award, 2016

- Technology Innovation Award (GENP16), Italy, 2016

- IFT W. K. Kellogg International Food Security Award, United States, 2016

- American Oil Chemist Society Corporate Achievement Award, United States, 2013

Presentation examples

- Juliano, P. Technology applications to develop a continuous olive oil process, 1st Latin American Congress of Olive Oil (CLAO2020), online, 19-22 April, 2021, Montevideo, Uruguay

- Juliano, P., Tamborrino, A., Leone, A., Romaniello, R. Industrial olive oil extraction plant combining microwaves and other process enhancement systems, 21-23 September, 2019 Melbourne, Australia

- Juliano, P. Swiergon, P., Mansour, P., Knoerzer, K, Smith, R., Muller, P. Megasonics application in EVOO processing, National 2018 Olive Oil Industry Conference and Exhibition, 18-20 October, Wagga Wagga, NSW, Australia

Communications and research dissemination

Through well maintained international networks and partnerships, the CSIRO research team has facilitated international dissemination of the research outputs. Notably this includes media in Italian Olive Oil industry publications and Italian Academic conferences.

Outcomes

Key outcomes from the Megasonics project include the following.

- Successsful demonstration of the Megasonics technology in a commercial environment

- Ongoing engagement between CSIRO and equipment suppliers for potential future commercialisation of the technology

- Engagement with the Australian Olive Association

- Recognition of research achievement and increased interest from research partners and industry. For example, demonstrated through invitations to present at the National Olive Industry Conference in 2018, dissemination of research through Australian and Italian olive oil industry trade publications, interest from Agroland (Uruguay) as well as Boundary Bend Ltd. to work or continue working with CSIRO, and nomination as a finalist in the ANSTO Eureka Prize for Innovative Use of Technology in 2018.

Impacts

Economic

Should the technology progress to a full size commercial prototype and be adopted by industry there is:

- Potential for producer surplus through increased industry returns and due to increased recovery of olive oil (up to 3.7%) and/or reduction in processing costs and time.

- Potential for increased consumer surplus through lower prices if increased domestic production has this effect.

- Potential for access to new export markets for Australian olive oil that do not currently allow the use of enzymes in extra virgin olive oil production if enzyme use removed.

- Potential for an expansion in market opportunities and producer surplus for olive oil equipment manufactures.

- Potential for government surplus through new royalty revenue streams for Australia from abroad should the technology be exported to the global industry.

Environmental

Potential for reduced food waste through the increased recovery of oil from olives that is otherwise lost.

Social

- Potential for links to improved health outcomes through production of olive oil with a higher content of phenolics and antioxidants.

SIEF’s Role

The SIEF project played an instrumental role in de-risking the scale-up demonstration in an olive oil commercial facility for the first time by enabling the purchase of a larger number of transducers required for a larger vessel. CSIRO researchers noted that the industry contributed in-kind time and equipment for research trials but was not willing to invest cash. Without the SIEF financial cash investment the demonstration of the Megasonics technology at 3 tonnes/hour would not have been possible.

The SIEF funding enabled:

- Bringing together of CSIRO researchers and industry and the build, installation and testing of Megasonics in the olive oil industry for the first time.

- Advancement of the Megasonics technology in olive oil processing from a Technology Readiness Level (TRL) of 5 (conceptual design and prototype demonstration) to a 7 (detailed design and assemble level build). As a result, the technology has also reached the commercial readiness level of 2 (commercial trials of the technology of a small scale).

- The first successful demonstration of the potential of the technology to provide productivity and quality benefits to olive oil extraction in a commercial environment.

Future Work

The funding and support from industry partners and SIEF has been invaluable in reaching the first stage of a commercial prototype. The ultimate success of this work is heavily dependent upon further execution beyond this stage for successful translation and commercialisation of this work.

Academic publications

Amarillo, M., Gámbaro, A., Ellis, A.C., Irigaray, B., Lázaro, J., Tamborrino, A., Romaniello, R., Leone, A., Juliano, P. (2021). Shelf life of extra virgin olive oil manufactured with combined microwaves and megasonic waves at industrial scale. LWT – Food Science and Technology, 146 111345

Amarillo, M., Pérez, N., Blasina, F., Gámbaro, A., Leone, A., Romaniello, R, Xu, X-Q., Juliano, P. (2019). Impact of sound attenuation on ultrasound-driven yield improvements during olive oil extraction. Ultrasonics Sonochemistry, 53, 142-151.

Leone, A., Romaniello, R., Tamborrino, A., Xu, X.Q., Juliano P. (2017). Microwave and megasonics combined technology for a continuous olive oil process with enhanced extractability. Innovative Food Science & Emerging Technologies, 42, 56-63

Juliano, P., Augustin, M.A., Mawson, R., Knoerzer, K. (2017). Advances in high frequency ultrasound separation of particulates from biomass. Ultrasonics sonochemistry. 35, 577-590